I'm just back from the machine shop with a tidy pile of laser cut parts, and reckon this would be a good time to start a build log to compile details for later how-to articles... presuming success.

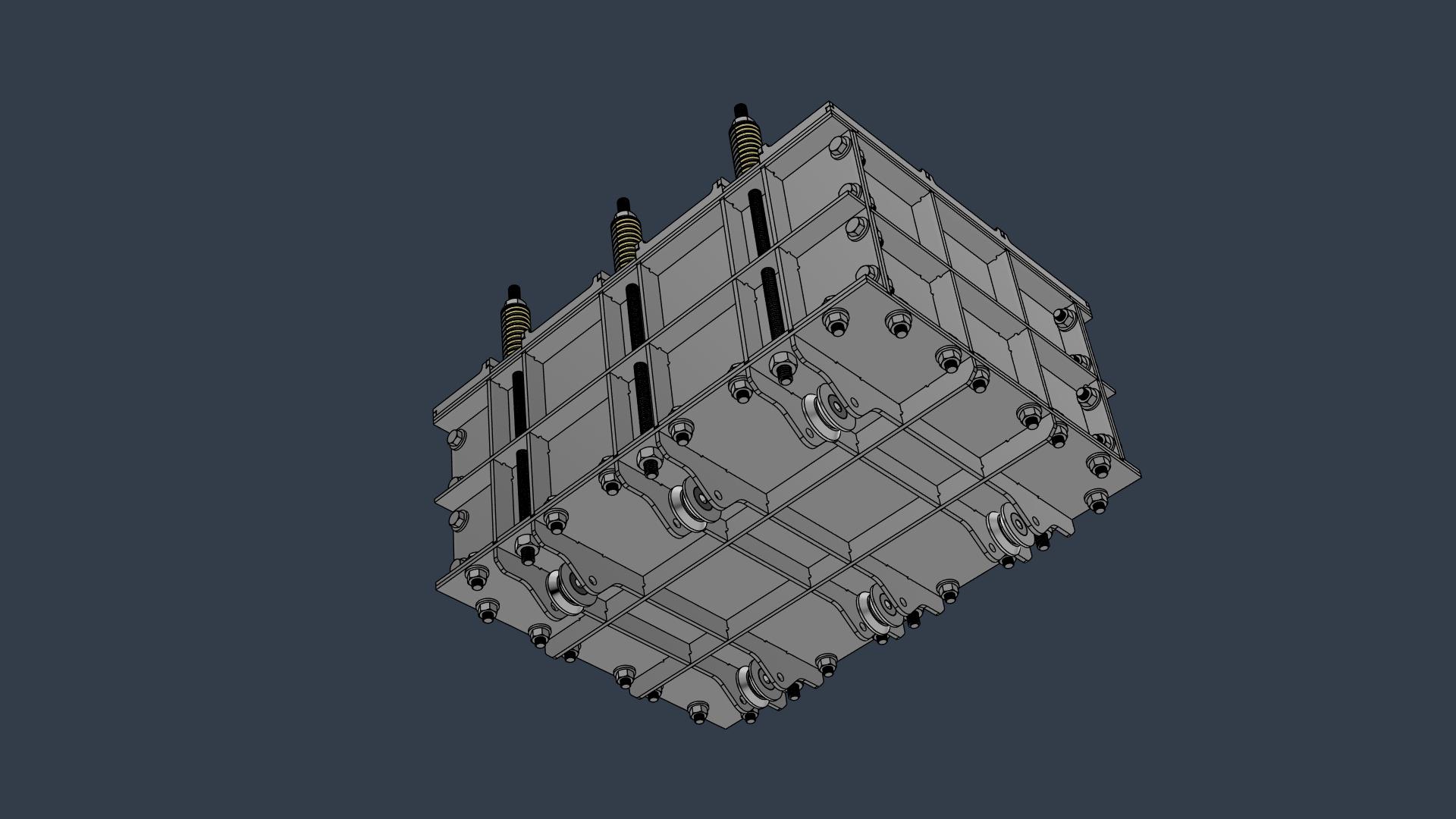

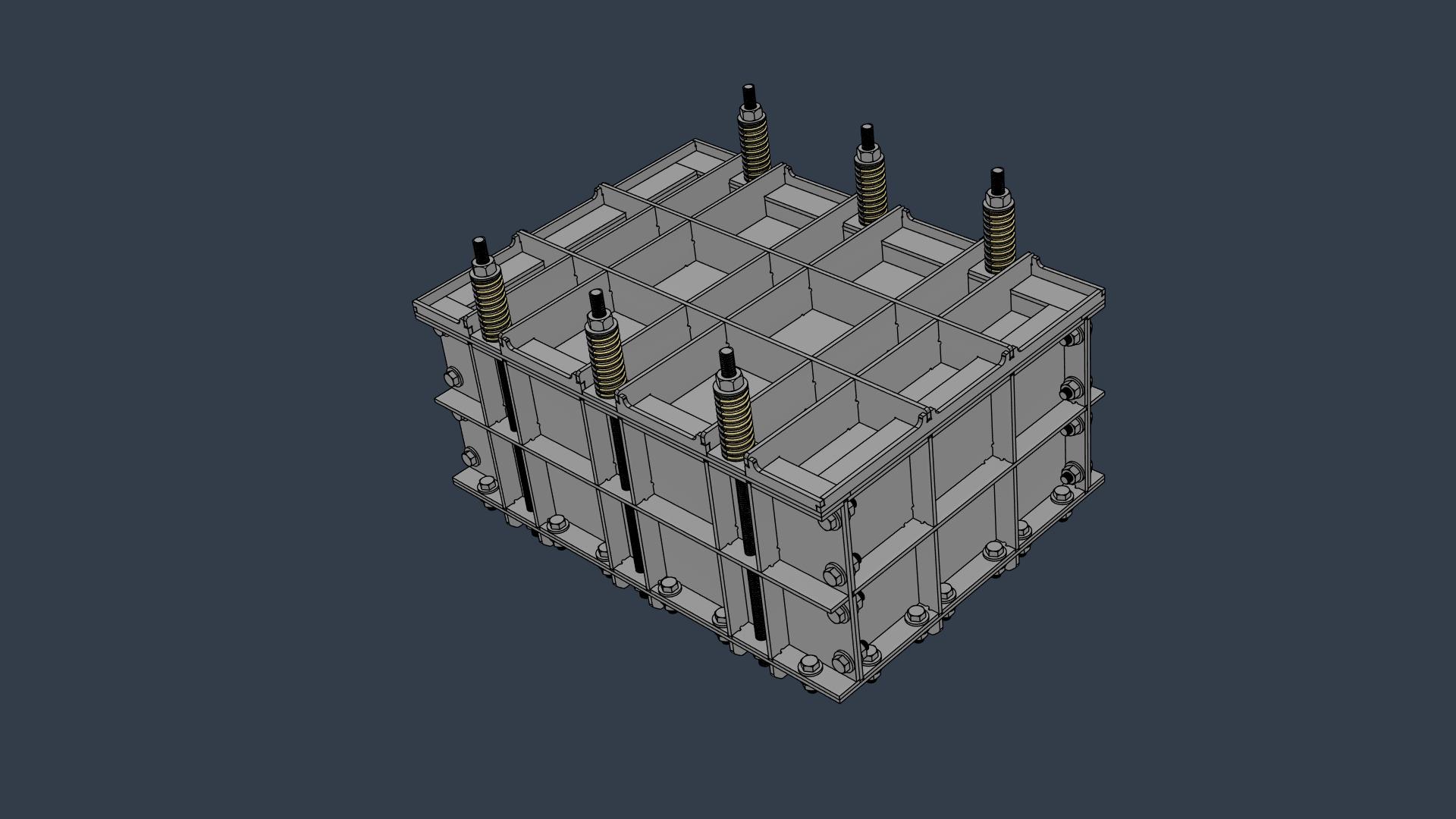

First, what and why. As the name suggests, the mold produces large billets of plastic- ~14.5" x 20.5" x 7.75", or 80 lbs of HDPE (37 cm x 52 cm x 19.7 cm, 36 kilos), for fabrication/machining. (By contrast- if my math is right -a 1 m x 1 m x 1 cm sheet weighs ~ 21.2 lbs/9.62 kilos.) I plan to machine constituent blocks from the billets for monumental sculptures.

It might be more accurate to call this a "self-pressing mould", as the compression mechanism is built into the mould itself, in the form of manually-torqued acme screws and die springs, foregoing the need for an encompassing press and jack. The mould possess no integrated heating elements; rather, this initial version is designed (and sized) to utilize a conventional domestic convection oven for both melting and annealing the plastic.

I'll cover some of supporting processes in the days to come in this space, such as designing for laser cutting, adapting designs to available stock parametrically, stock selection, sourcing high-temperature parts, working with suppliers and machine shops, welding and machining, adapting an oven, handling moulds and stock, and developing soak and annealing schedules.

For now I'll, leave off with some eye candy- a few renderings of the mould, and the fresh cut parts next to a salvaged (and repaired) oven. (edited)

1

1