One Army

🌏 Regions / 🌽africa

Chats for all countries in Africa.

:flag_za: plants our flag, like this:  (edited)

(edited)

basically still at square one

Yes. Most of us are. But connecting with interested people is the first step.

basically still at square one

Yes. Most of us are. But connecting with interested people is the first step.

Well, it seems Maker Station has a laser cutter. But I've seen no direct offers of assistance.

I've gotten some clarity on that: It's not the kind that can cut metal. Only plastic and wood.

site: https://davehakkens.nl/community/forums/. That limits the search to whatever is on the "old" forums.

On Discord, just click the "looking glass" icon up at the top and put in your search words. That searches the entire server chat history and displays results chronologically, from newest to oldest. You can refine searches with the options on the search screen.

delivery of container is the expensive part

Ja... Just another reason to develop reliable modular structures. Like RepRap 3D-printers. The 1st workspace can build the 2nd. The 2nd can build the 3rd... and so on.

[@]Noeline#4652 before you post the message, and like this @Noeline in the posted message. You should see a list of server users whenever you type "@". (edited)

Actually, from New York

I suspect another invite link that points to the wrong channel

we operate a plastic studio in Durban www.upcyclethefuture.com

Thanks @mechanic.

Noted. I knew you made the combs and stuff. Wasn't sure about the scope of the operation.

are there any small independents, or is it all tied up by big business ?

Good question. No viable small operators that I can think of. Unless you maybe consider small artists' studios who upcycle trash into niche "artsy-fartsy" stuff, mostly to sell to rich foreign tourists.

The main problem with our economy is that production capacity is still largely consolidated into the hands of industrialists.

Also, SA produces it's own virgin plastic locally. (Mostly, if not exclusively from Sasol.)

The industry has a lot of clout, and plays a lot of "greenwashing" PR games in the media, regarding recycling.

We may, ironically, be well ahead of European countries in terms of recycling capacity.

But, also ironically, that changes the economics of how PP can work here. At least, that's what I think. Proper, unbiased market research would help a lot, to answer that question. (edited)

the South African mentality is never to work together

So much for ubuntu, huh?

Probably a better idea to get some items made first before going ‘all-in’

Yes, I haven't come across any Collection Points / shredding stations. Mostly because there's hardly any secondary market. Locally, it's all about 3D-printing. But then they complain about the import cost of good quality filament. "Rich boys with expensive toys."

The commercial studios can probably courier you a bucket or two of flakes, if you don't mind the fees.

How’s the V3 holding up?

I don't have regular access to a shredder. I can't really tell you, yet. I've only seen one working machine in CTP.

I also need to learn the CAD basics. Then trying to negotiate bulk prices with my local laser-cutter might be worth the effort.

It's the same basic problem: Without a workspace, how do I justify the cost? I have to start from scratch. And, so far, local, unsubsidised maker spaces have not proven to be sustainable. At least, not generally.

Personally, I think the local mindset is wrong. But there isn't much to be done about that.

It would be backward thinking to create a plant like this which still negative impacts the planet through pollution.

Well, it depends on how you think about it.

The whole reason an opportunity for micro-factories exists, is because big business continuously fails to step up and take responsibility. Hence the global Plastic Crisis.

And anything we do as isolated individuals, is laughably small compared to the sheer scale of ecological damage done by plastic and plastic processing every day.

If you do nothing about it, obviously, you do nothing.

If you wait for governments and industries to wake up, you might as well just do nothing.

If you engage in decentralized, micro-manufacturing, you're probably still doing some harm. But it's slightly less harm. And that excludes whatever economic benefits there might be.

As I've said before: (https://discordapp.com/channels/586676777334865928/598855130066190377/722099555054649495 )

I think our thinking should be split into related, by ultimately separate categories.

• Hobbyists

• Fundraising projects

• Semi-industrial

• Tackling the plastic crisis

You can do all of them, but don't confuse one for the other.

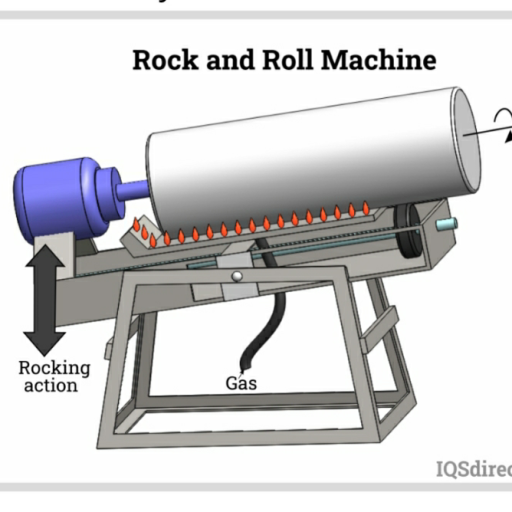

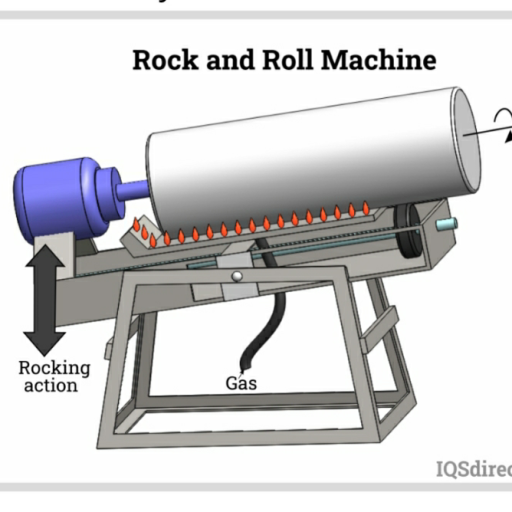

the specifications / dimensions

I missed the more focused country groups, that was great for building a local network

I agree that African countries need extra help to build local collaborations. I'm still looking for a system to replace the Precious Plastic map we had during V3. I think there's a way to use a map to connect people without flooding the map with useless pins. But it seems either no-one has implemented the idea, or no-one but me has thought of it.

I'm also considering a Discord-based system. But we'll have to do it on a separate server, with a lot of automation.

in:[#]plastic-sorting has:link is probably your best bet. We don't have a project collection document yet. (edited)

# showcase channel on the Discord server, https://preciousplastic.com/solutions/products, and the community tutorials at https://community.preciousplastic.com/how-to

Look through the Academy playlist for basic information on building machines:

https://www.youtube.com/playlist?list=PLtYgsstkMPuXdOmvoUYAc0oDoFlk_Ztsp

You can find the machine schematics at:

https://community.preciousplastic.com/academy/download

Buy ready-made machines, unassembled machine kits, moulds and recycled plastic products on the online Bazar:

https://bazar.preciousplastic.com/

Check the pinned messages in all channels on this server for additional information.

For information on more specific topics, you can search this server (click the looking glass

I missed the more focused country groups, that was great for building a local network

I agree that African countries need extra help to build local collaborations. I'm still looking for a system to replace the Precious Plastic map we had during V3. I think there's a way to use a map to connect people without flooding the map with useless pins. But it seems either no-one has implemented the idea, or no-one but me has thought of it.

I'm also considering a Discord-based system. But we'll have to do it on a separate server, with a lot of automation.

Anybody here from Ghana?

Several people have said they are. Search the Discord chat for "Ghana."

Importing kits tends to be very expensive, because of the shipping weight. Thoroughly search the Bazar to find a reliable kit supplier or machine builder as geographically close to you as possible. That also helps with measurement and part compatibility. South Africa is a bit of a "hybrid." Some commonly available materials and parts come from both East and West. So, it's not entirely Metric or Imperial.

https://bazar.preciousplastic.com/

to crush biodegradable waste from fruits vegetables and tree branches and others would a normal Shredder work?

You should double check the reported output capacity and specifications of the V4 and V4 Pro Shredder.

The V3 apparently struggled to crush PET bottle necks. I think that implies that wood and similarly hard fibres would be a no-go on that one. So, look at the V3's "big brothers" or consider a commercial / industrial woodchipper.

no response

Yes, common problem. It's why a constantly "live" user database that requires user interaction is necessary in our part of the World.

The pandemic has added many reasons why people might disappear.

But even before the virus, most local map pins were useless. (edited)

after pressing, can one use the plastic sheets the same way you would use wood?

Other than trying to collect plastic dust, to prevent pollution, I think it can be worked pretty much like wood. I haven't seen any specific recommendations regarding screws.

From my own limited experience, regular wood screws work as expected, more or less like with very soft wood. (But I've only used original production plastic, not re-melted.)

The surface maybe scratches and dimples little bit easier on polypropylene.

And screws tend to dig out little curly strings rather than flakes. They can jam up screw holes more easily.

So, almost the same as soft wood, but be more gentle.

after pressing, can one use the plastic sheets the same way you would use wood?

Other than trying to collect plastic dust, to prevent pollution, I think it can be worked pretty much like wood. I haven't seen any specific recommendations regarding screws.

From my own limited experience, regular wood screws work as expected, more or less like with very soft wood. (But I've only used original production plastic, not re-melted.)

The surface maybe scratches and dimples little bit easier on polypropylene.

And screws tend to dig out little curly strings rather than flakes. They can jam up screw holes more easily.

So, almost the same as soft wood, but be more gentle.

3

3

1

1

Recently registered a business to produce the bricks

Where?

Recently registered a business to produce the bricks

Where?

Before SABS can write it into their documents for universal use...

Having clarity on that would be significant progress.

combine precious plastics with building homes for poor, homeless, disadvantaged

This was posted previously:

https://discordapp.com/channels/586676777334865928/598855130066190377/792429220470063124

https://discord.com/channels/586676777334865928/598855130066190377/792429220470063124

In South Africa, we're still trying to get clarity on the Bureau of Standards requirements for building materials.

One main concern is fire safety, since fires spread quickly in our shanty towns, where structures are typically wood and sink plates. Furthermore, high UV radiation from bright sunlight and relatively high summer temperatures should be considered. Plastic and sand roof tiles are already sold commercially.

My interest in experiments is also concerned with how "modular" structures can be, while still being safe.

Since they are technically supposed to be temporary, regardless of practical reality. (edited)

6

6 1

1

Sou Antonio e faça parte de uma comunidade do Plástico Precioso na cidade de Cajazeiras no nordeste do Brasil!

Estou buscando fazer um intercambio com paises lusófonos no continente africano para participar de um evento que estamos organizando para novembro desse ano!!

Sou Antonio e faça parte de uma comunidade do Plástico Precioso na cidade de Cajazeiras no nordeste do Brasil!

Estou buscando fazer um intercambio com paises lusófonos no continente africano para participar de um evento que estamos organizando para novembro desse ano!!

Sou Antonio e faça parte de uma comunidade do Plástico Precioso na cidade de Cajazeiras no nordeste do Brasil!

Estou buscando fazer um intercambio com paises lusófonos no continente africano para participar de um evento que estamos organizando para novembro desse ano!!

Sou Antonio e faça parte de uma comunidade do Plástico Precioso na cidade de Cajazeiras no nordeste do Brasil!

Estou buscando fazer um intercambio com paises lusófonos no continente africano para participar de um evento que estamos organizando para novembro desse ano!!

2

2