One Army

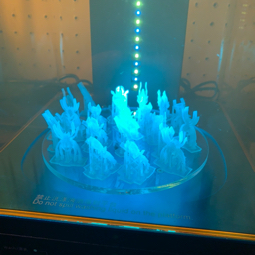

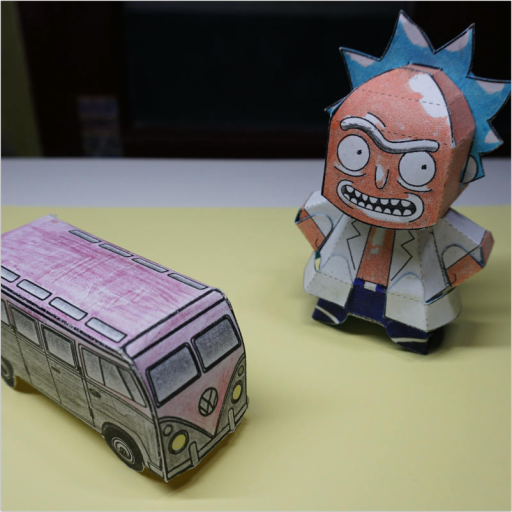

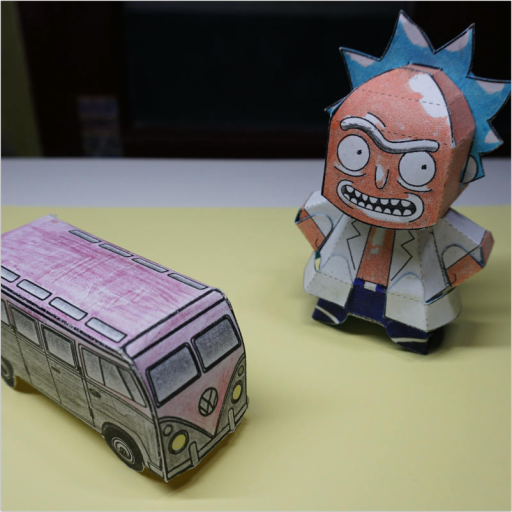

Precious Plastic / archived-showcase

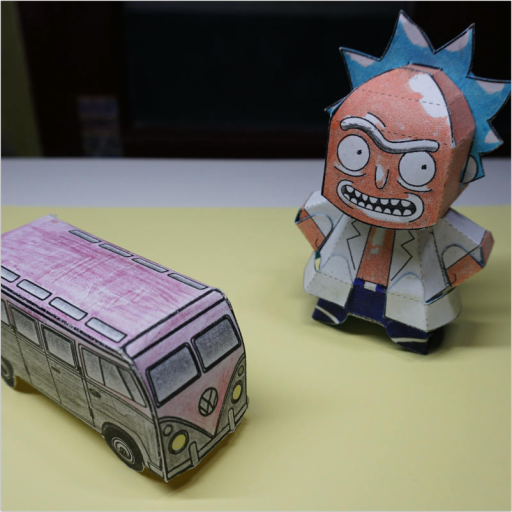

Share pictures of your machines, products and workspace. We like images and videos here

6

6

tell us if there is a plan to make some more ?

Better yet: A How To on the site for making the coins. (edited)

What sizes are we talking? I'm not sure.

2

2

1

1

3

3

1

1

Can i use the term “precious plastic“ to describe these items?

As far as I know, the name is not trademarked in any way. (Maybe HQ should review that thinking.

1

1

3

3

2

2

?

? 2

2

2

2

1

1

3

3 1

1

15

15 6

6

11

11

5

5

3

3

2

2

1

1

1

1

4

4

2

2 2

2 3

3

4

4 5

5

2

2 3

3

1

1

3

3 4

4

3

3 1

1 3

3

4

4 1

1

5

5 5

5

1

1

4

4 1

1

1

1

2

2 6

6

5

5 3

3 1

1 1

1

4

4

2

2

1

1

2

2

4

4 4

4

2

2

11

11

2

2

1

1

5

5

1

1

(@Hugh&@Communication Contributor )

https://www.instagram.com/p/CYGkITUJNkW/

(@Hugh&@Communication Contributor )

https://www.instagram.com/p/CYGkITUJNkW/ Instagram

Instagram

(@Hugh&@Communication Contributor )

https://www.instagram.com/p/CYGkITUJNkW/

(@Hugh&@Communication Contributor )

https://www.instagram.com/p/CYGkITUJNkW/

(@Hugh&@Communication Contributor )

https://www.instagram.com/p/CYGkITUJNkW/

(@Hugh&@Communication Contributor )

https://www.instagram.com/p/CYGkITUJNkW/  Instagram

Instagram

Instagram

Instagram

Instagram

Instagram

5

5

3

3

7

7

4

4

10

10

2

2

1

1

Instagram

Instagram

10

10 4

4

4

4

1

1

2

2

7

7

8

8

Instagram

Instagram

Instagram

Instagram  3

3

3

3

Instagram

Instagram

Instagram

Instagram

Instagram

Instagram

Instagram

Instagram