One Army

Precious Plastic / archived-plastic

Chatting and nerding about plastic. Saftey and fumes ,melting temperatures, chemical bounds etc.

any idea how to recycle 7(Others) plastic type ?

Not without proper identification and /or experiments (like with all types of plastic, depending on manufacturer, additives, etc.)

Other (7) can also be a blend. So, it's tricky. NIR identification is something to aim for. That's what #deleted-channel is about. (edited)

I don't think pollution is their goal.

Not directly, no. Because they are not villains from a Captain Planet cartoon. That would be insane troll logic.

What they want is to not be accountable, morally and (by extension) financially.

And if you think the tentacles of Big Oil are not a part of this... well, sorry... you're naive.

it's not that they're sacrificing the environment for their goal, they don't even consider their actions to affect the environment.

Yes. Thanks a lot Neo-classical Economics and the Ivy League.

For giving us three generations of highly educated morons.

The gift that keeps on giving.

I have long theorised that what might be considered "mental illness," under different circumstances, can actually be induced, en masse, if the same absurdities are just repeated often enough, with enough confidence.

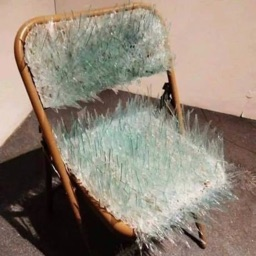

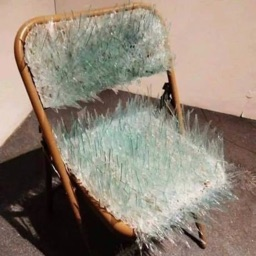

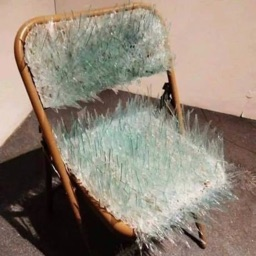

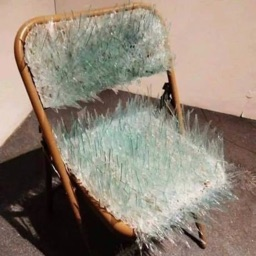

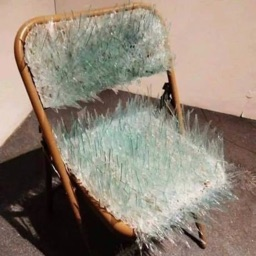

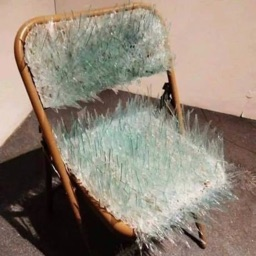

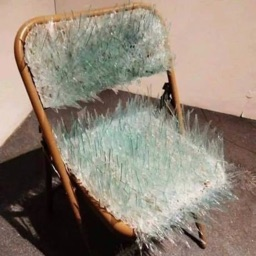

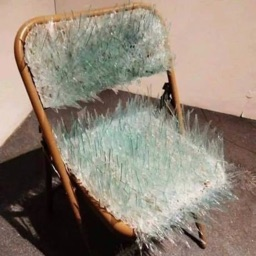

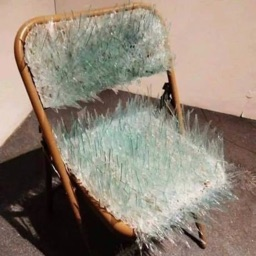

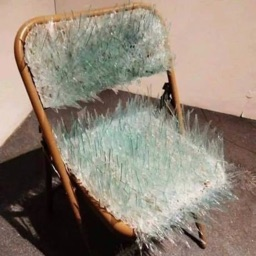

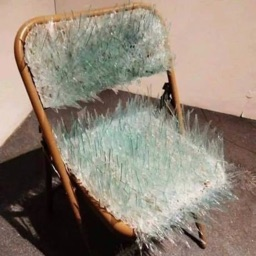

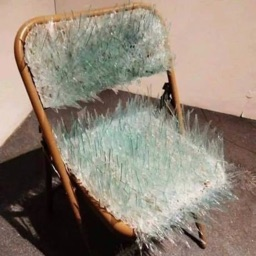

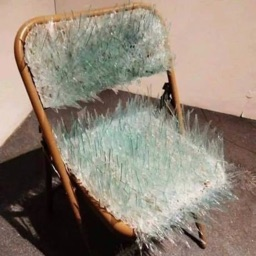

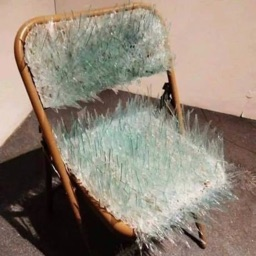

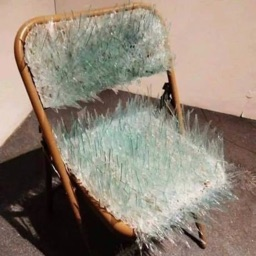

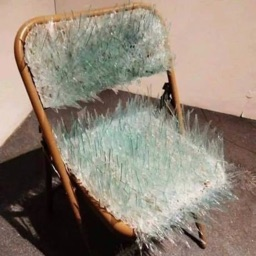

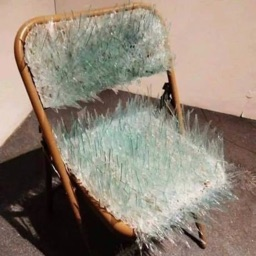

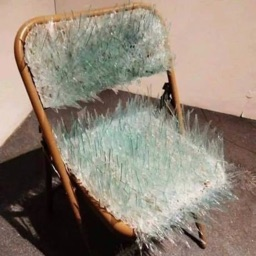

Anyone here already make plastic beam? Is the plastic beam strong enough to make a furniture?

Well, the V4 team has made a few pieces of all-plastic furniture so, in theory, yes.

it's not that they're sacrificing the environment for their goal, they don't even consider their actions to affect the environment.

Yes. Thanks a lot Neo-classical Economics and the Ivy League.

For giving us three generations of highly educated morons.

The gift that keeps on giving.

I have long theorised that what might be considered "mental illness," under different circumstances, can actually be induced, en masse, if the same absurdities are just repeated often enough, with enough confidence.

I wouldn't be so sure about it's readiness for practical applications outside of proof-of-concept/show-piece mindset

Maybe it's about the mixture "recipe."

How [...] recycle milk box ?

Just to be clear: You're talking about Tetra Pak boxes? (edited)

Oh lol, thought you said "absorb what is useful, discord what is not"

It's Bruce Lee's famous Jeet Kune Do philosophy on learning practical self-defence.

But yeah... it depends what servers you're on

long-haul shipping companies transport bags of tags for free, whenever they have some empty space on their trucks.

You basically have to start thinking like a drug smuggler.

Situating compressors at fish processing plants where they have huge stock of waste EPS boxes.

That's fitting, because the whole website is "fishy," if you ask me.

@Deleted User: Petrol melts eps the best from my experiments

And then what are we supposed to do with the highly flammable, toxic goop?

I've been showered with petrol once, by accident. It's not an experience I will ever forget or want to repeat.

thats not plastic that has been used. Its way too clear.

Not necessarily. Some kinds of PET are fully recycled. Most companies just don't bother.

But as a general rule, yes, be sceptical of companies' claims.

execute the board members in a public square...

Ah, yes... there's a little Fascist in all of us, just clambering to get out. That's why Fascism keeps coming back. It's like the common cold... it can't be cured, only managed. (Much like human stupidity in all its forms.)

I've also had it with those oppressive anti-murder laws that restrict my fundamental freedom to kill people who annoy me. I'm an African, dammit! Everyone knows Africans are special people who deserve special rights.

Anyway... it's a purely "academic" argument, because it makes no difference to what will actually happen until money is removed from politics.

I think it was Robin Williams who said politicians should wear jumpsuits with company patches on them, like race car drivers, so we can all see who owns them. (edited)

your "Virgin plastic" comes from oil stolen from one tribes land in canada

Who are you referring to?

Did you miss the part where I'm in Africa? I've never set foot on your continent.

I understand you are colonized. So is most of the World. It's big a "club." (edited)

Set it on fire

Sadly, one of the most common responses to plastic, in many scenarios.

1

1

"L" type profiles?

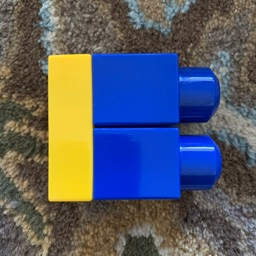

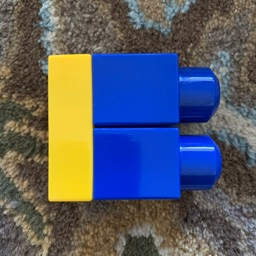

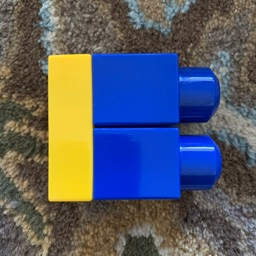

Lego looking bricks

All of that should be in the relevant How To's.

"L" type profiles?

Lego looking bricks

All of that should be in the relevant How To's.

can HDPE be translucent?

Yes.

But I'm not used to seeing it. I think most of our pharmacy containers are tinted PET. Commercial medication containers over here are almost always opaque HDPE #2.

I think especially for medication that is sensitive to UV light. (edited)

3

3

5

5

6

6

1

1

1

1

1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1

1

1

(edited)

(edited)

1

1

1

1

2

2

3

3

4

4

1

1

Instagram

Instagram

1

1

9

9

1

1

2

2

4

4

Instagram

Instagram

2

2

Instagram

Instagram

Instagram

Instagram