One Army

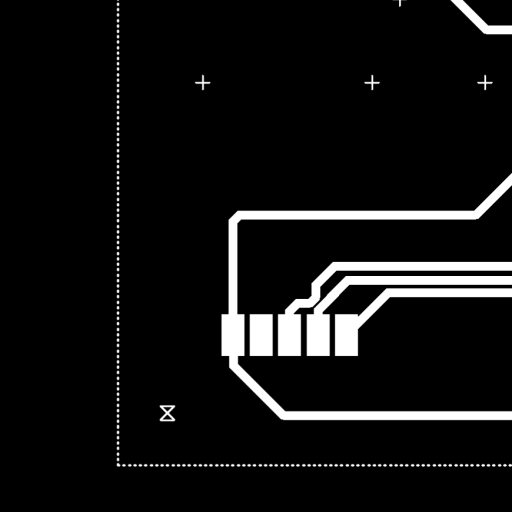

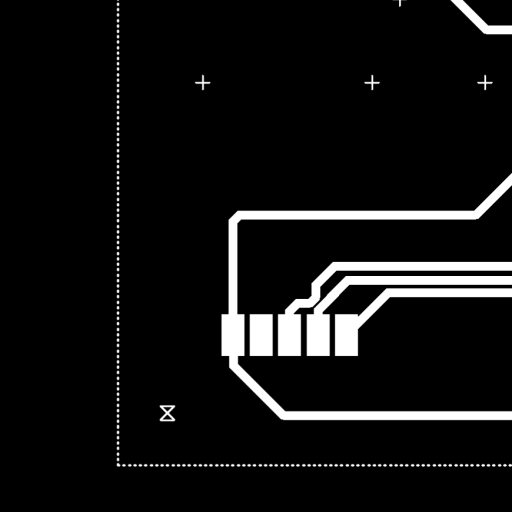

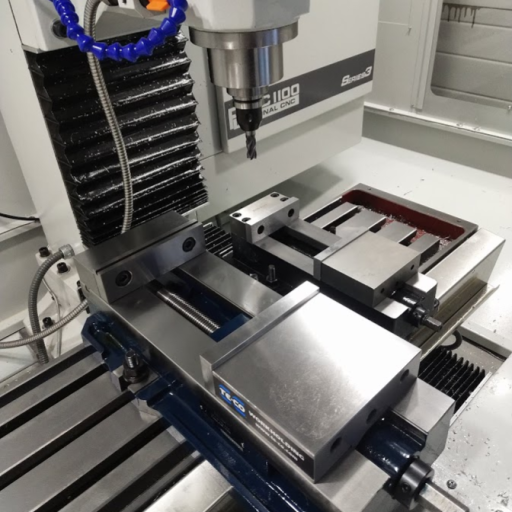

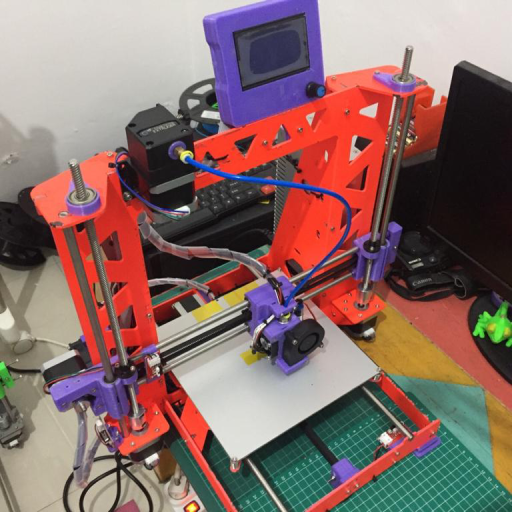

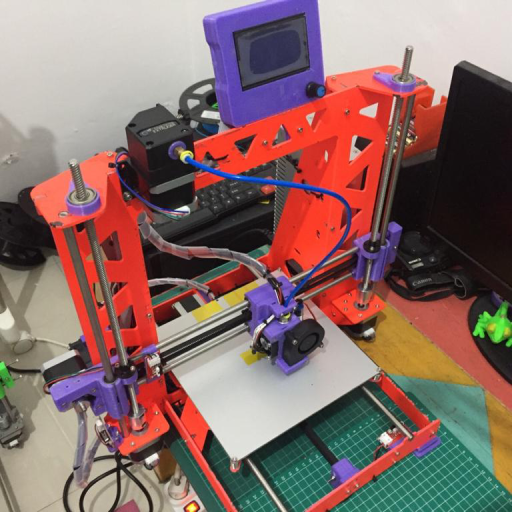

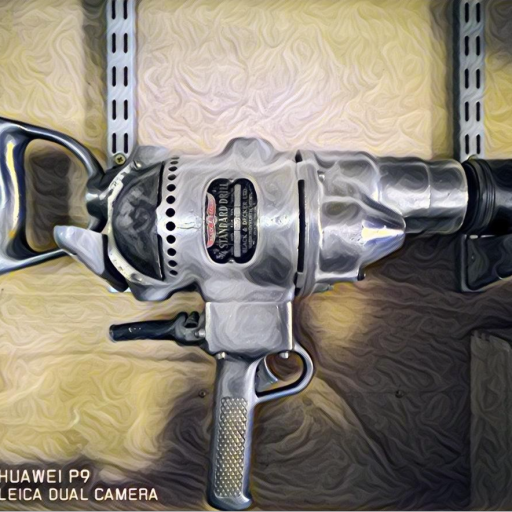

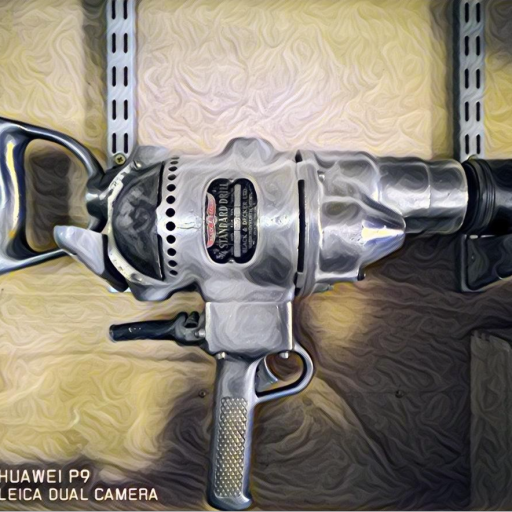

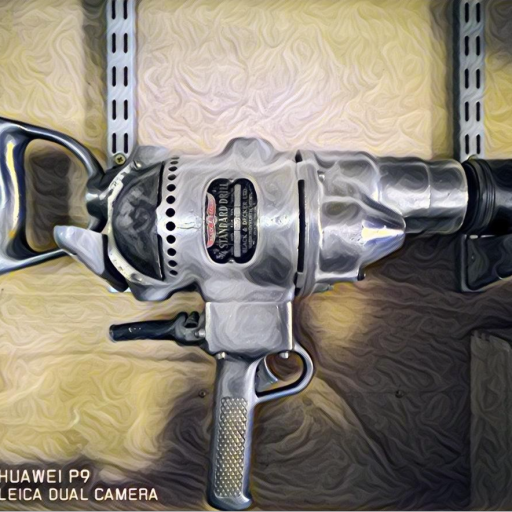

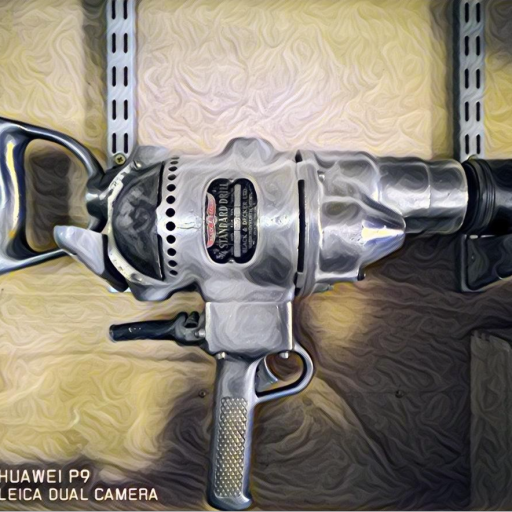

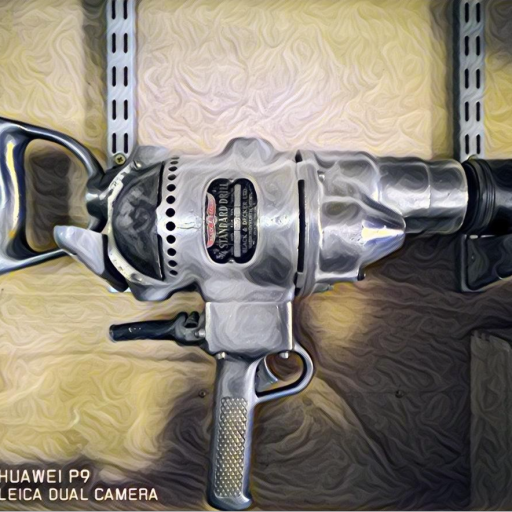

Precious Plastic / archived-machines

Channel for our engineers. All about all machines, pid controllers, drilling and maintenance

sorry can't paste a link

If you're on mobile, try a long press (about ½ a second) on the text input field. I get a "paste" pop-up. But I have a custom, full on-screen keyboard, so I generally Ctrl+V.

To copy text / URLs from a desktop screen, quickly, try an online QR generator.

if the multiple injections method was feasible, what sort of costing approximately

Yes, it's a big IF. And it would be sooo slow. But essentially it would be like extruding several beams, simultaneously. So the price of an extruder x N (the number you need.) Probably with some more complex control system (?)

I'm not really the person to ask. It's highly speculative. And most builders probably wouldn't even try and advise you to look at fully industrial machines.

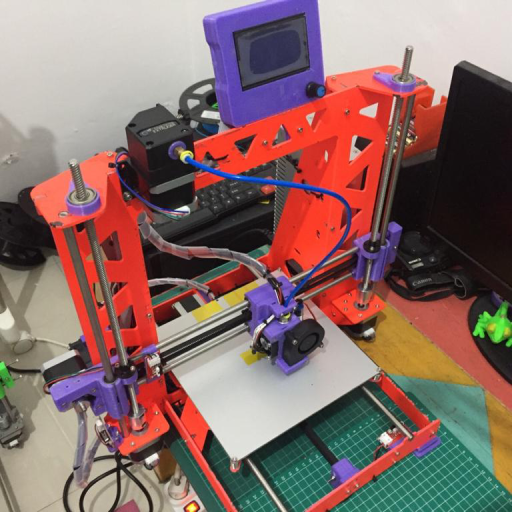

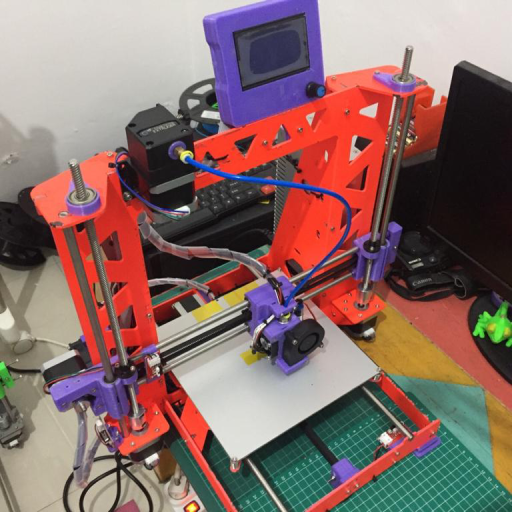

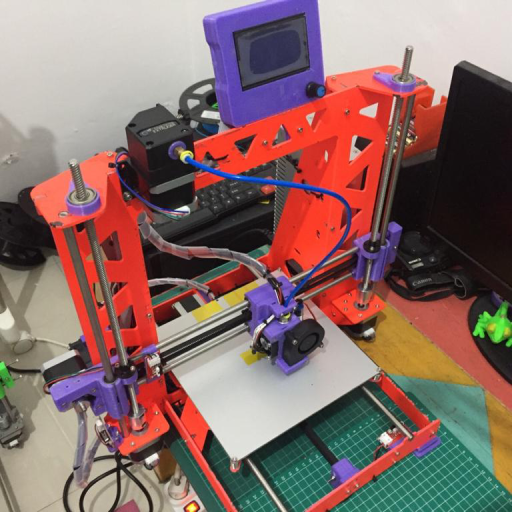

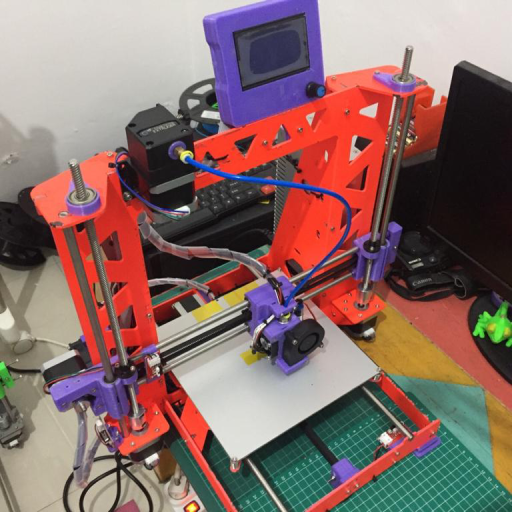

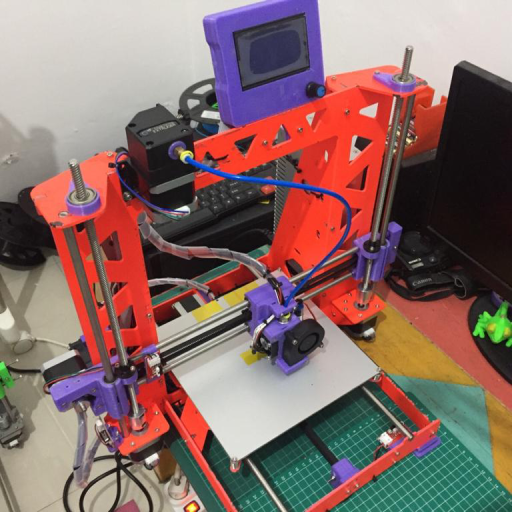

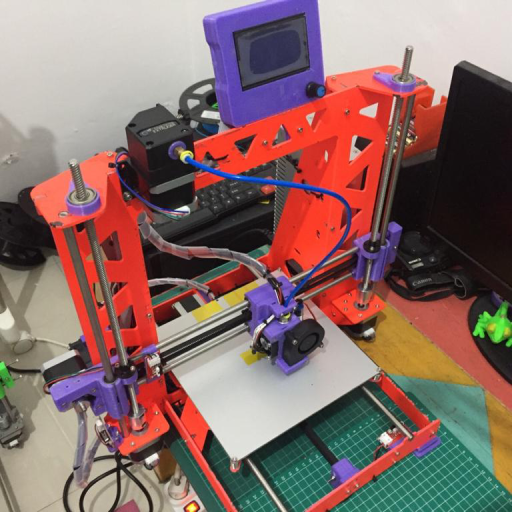

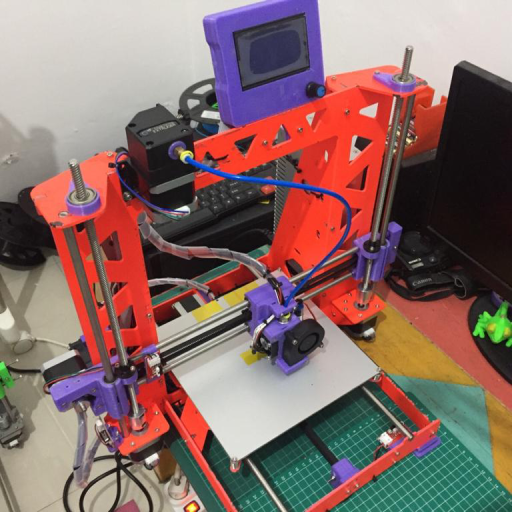

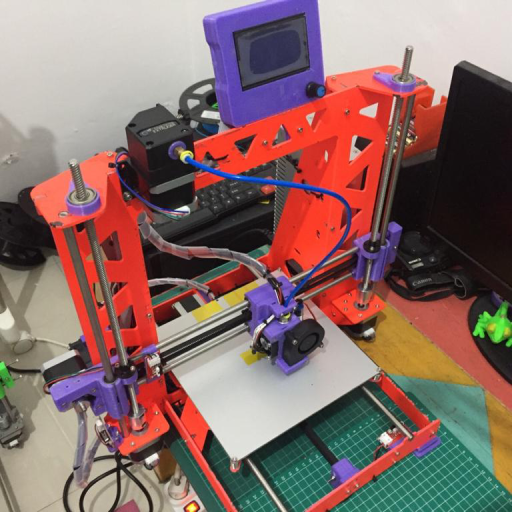

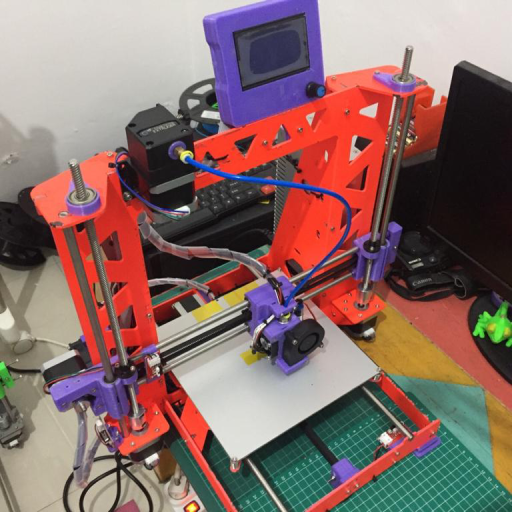

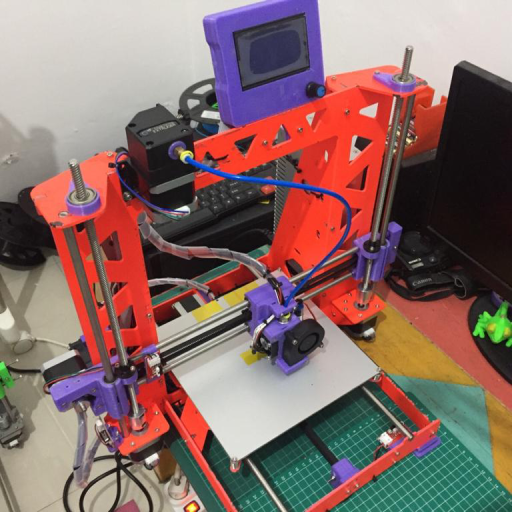

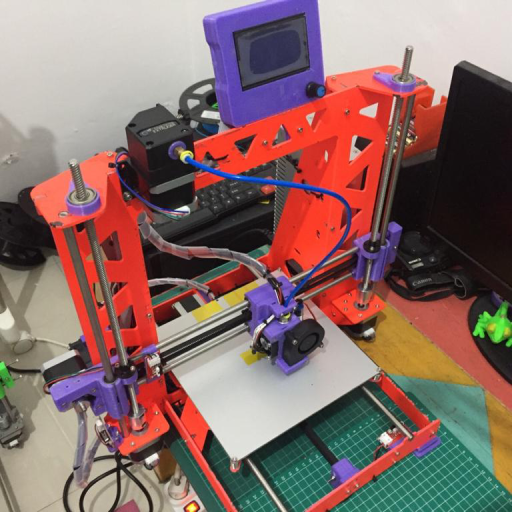

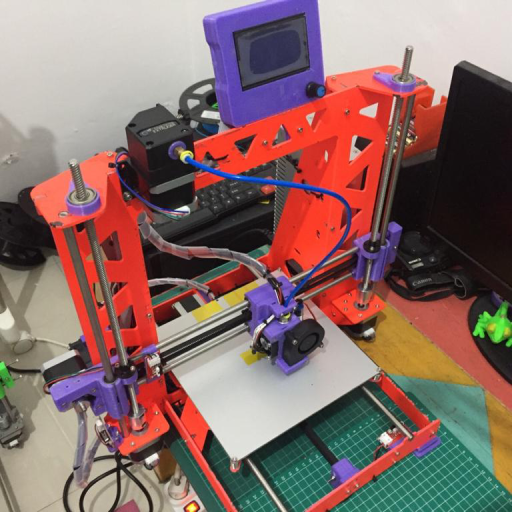

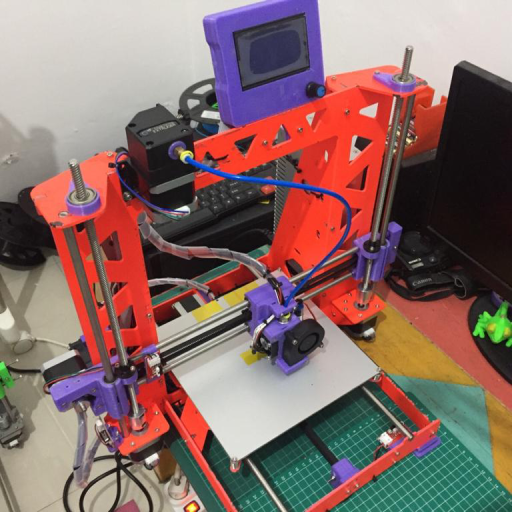

On a smaller scale, I'm thinking a really big, DIY 3D-printer is probably your best bet, for something with those dimensions. Unless heat welding two sheets on the large surface is feasible. Again, I have no idea.

TakeRep <User:User> [Num:Whole number]

Invalid arguments provided: Not enough arguments passed

I didn't realize we had a bot >.>

You can't have auto-roles on your server, without a bot.

PP Bot is based on YAGbot. But auto-role management is pretty much all it does. Most other functions are not configured.

TakeRep <User:User> [Num:Whole number]

Invalid arguments provided: "++ @Frederik C (ZA)" is not a whole number

she da best bot

Yeah... the ones programmed in Germany are very life-like. Almost human.

how to start learning!? :c

1

1

1

1

5

5

3

3

1

1

Instagram

Instagram

Instagram

Instagram

Instagram

Instagram

Instagram

Instagram

4

4

Instagram

Instagram

6mm = 37x37 cm

5mm = 56x56 cm

3mm = 38x38 cm

here's what I got from summing up all the areas and rounding up

Still looking for tips on enlarging the injection machine tho

Still looking for tips on enlarging the injection machine tho  ✨

✨

1

1

Zinc fumes are set free when galvanised steel is heated. These fumes are very toxic to breathe. Deposits of zinc from the fumes accumulate in the food. ... There are no USDA certified-safe galvanized metal cooking surfaces or containers.

1

1

3

3

1

1

3

3

1

1

1

1

1

1

1

1

6

6

6

6

1

1

1

1

1

1

1

1

1

1

1

1

Instagram

Instagram

2

2

Instagram

Instagram

Instagram

Instagram